内蒙古华唐铝业有限公司是一家从事科研、生产、销售为一体的轻量化铝合金产品生产企业。公司专注汽车轻量化,助力中国汽车智能制造。年产 12 万吨铝棒和 300 万只高精度轻量化铝合金车轮,其中智能制造锻旋铝合金车轮 80 万只,荣获了国家工信部批准“锻旋铝合金轮毂智能制造新模式应用”项目,并建成了国内锻旋铝合金车轮智能制造新模式工厂。

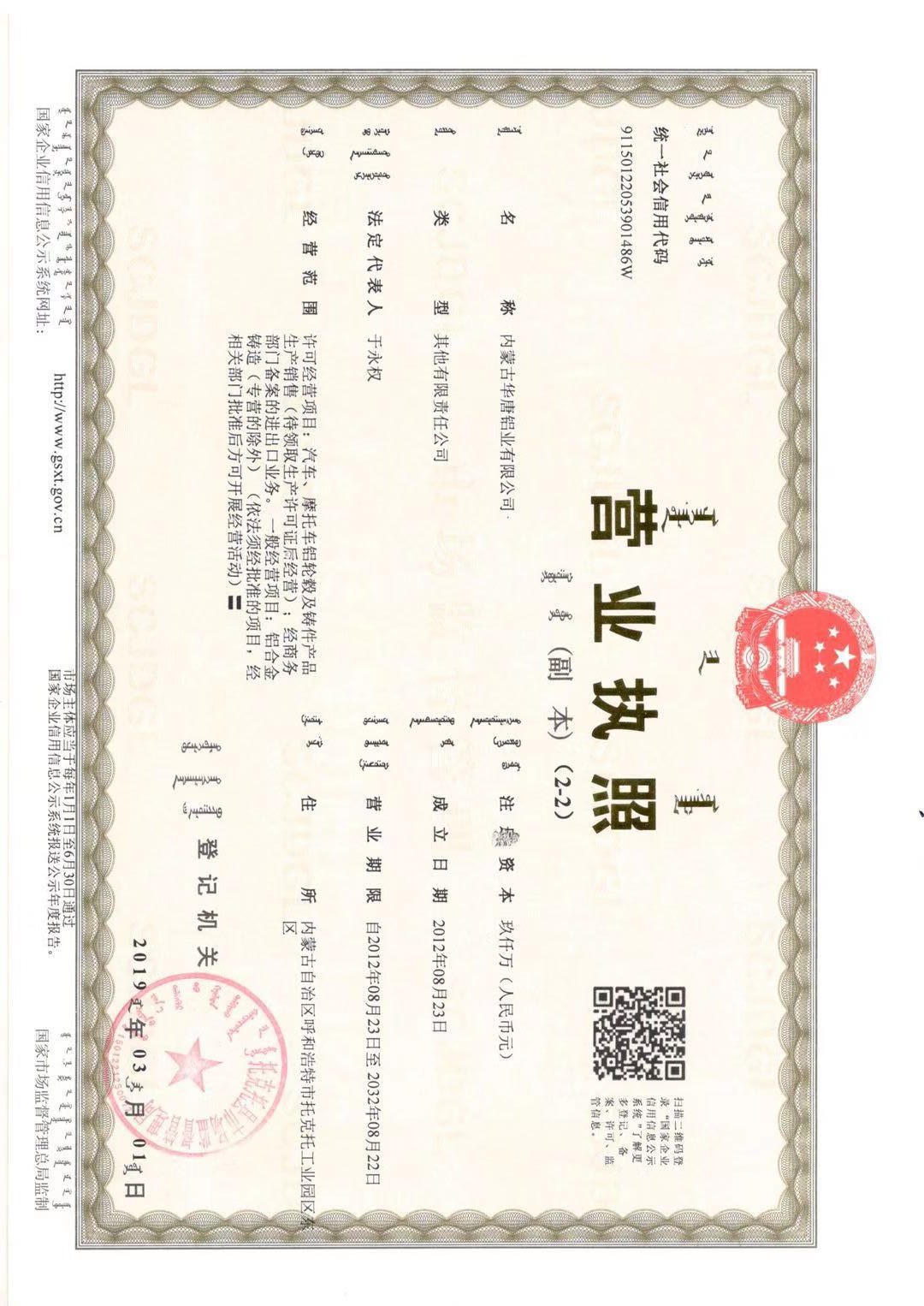

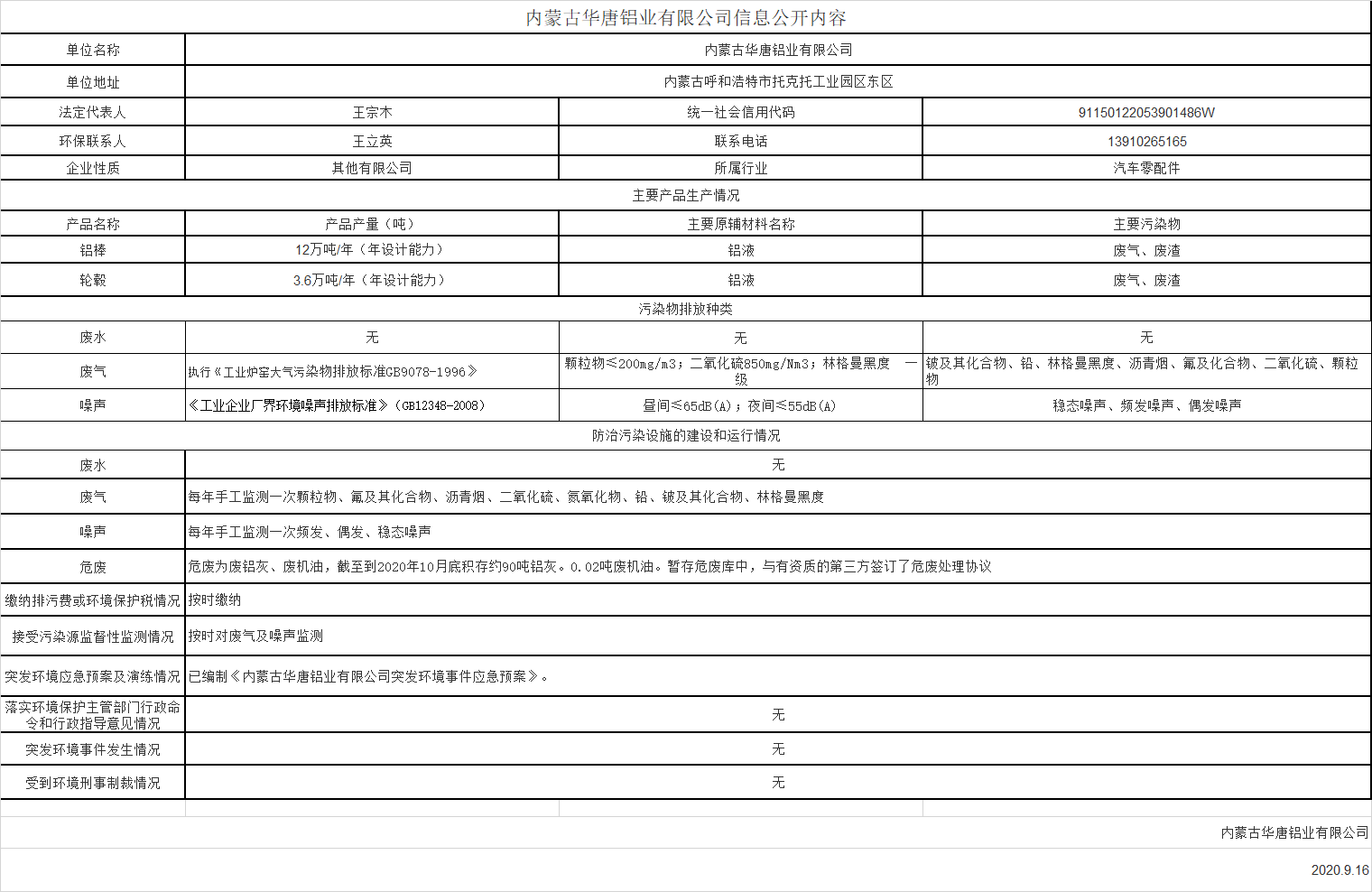

公司于 2012 年 8 月 23 日成立于内蒙古呼和浩特市托克托工业园区,注册资金 9000 万元人民币,总投资达 5.0 亿人民币,占地 95649 平方米,总建筑面积约5万平方米。

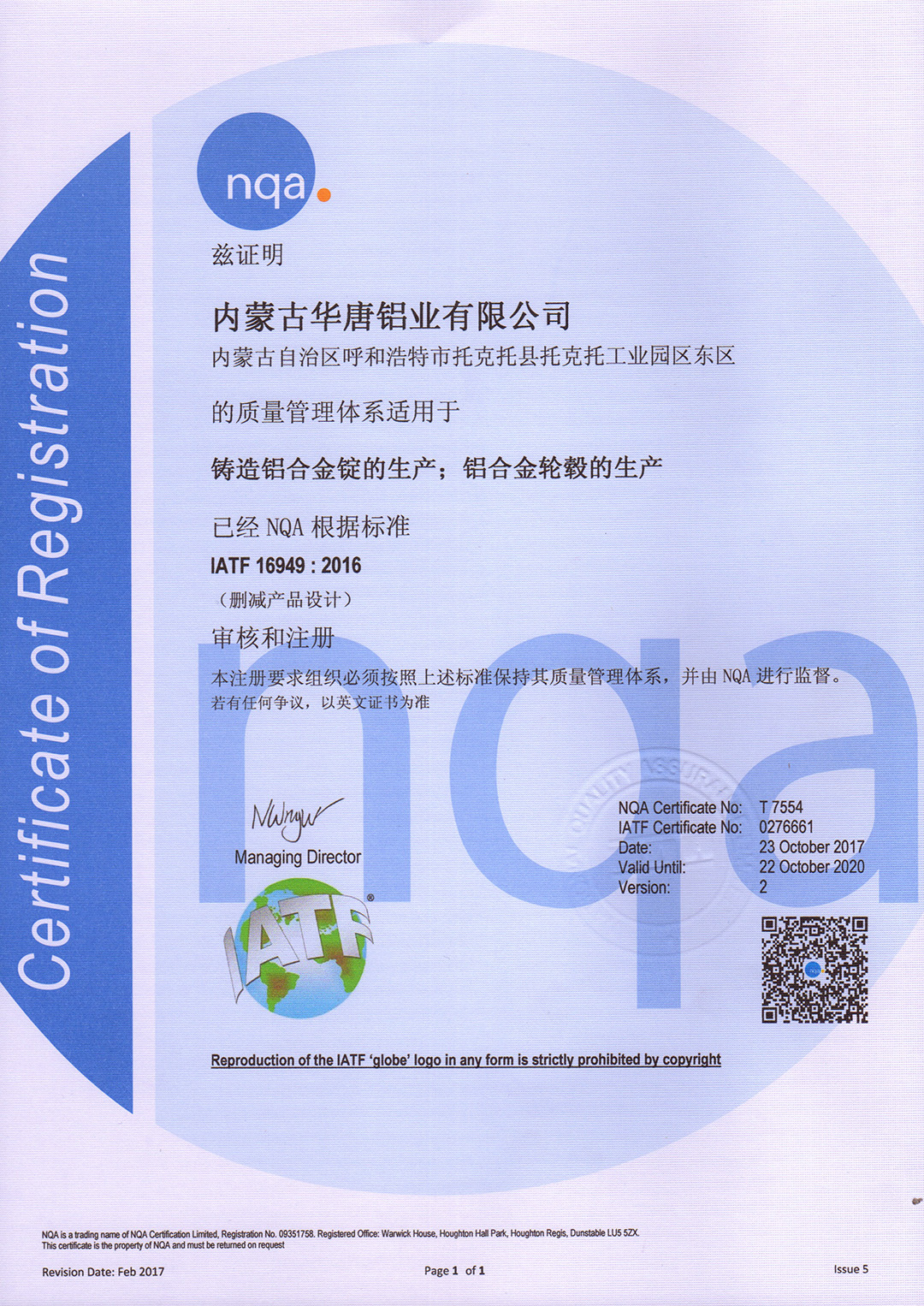

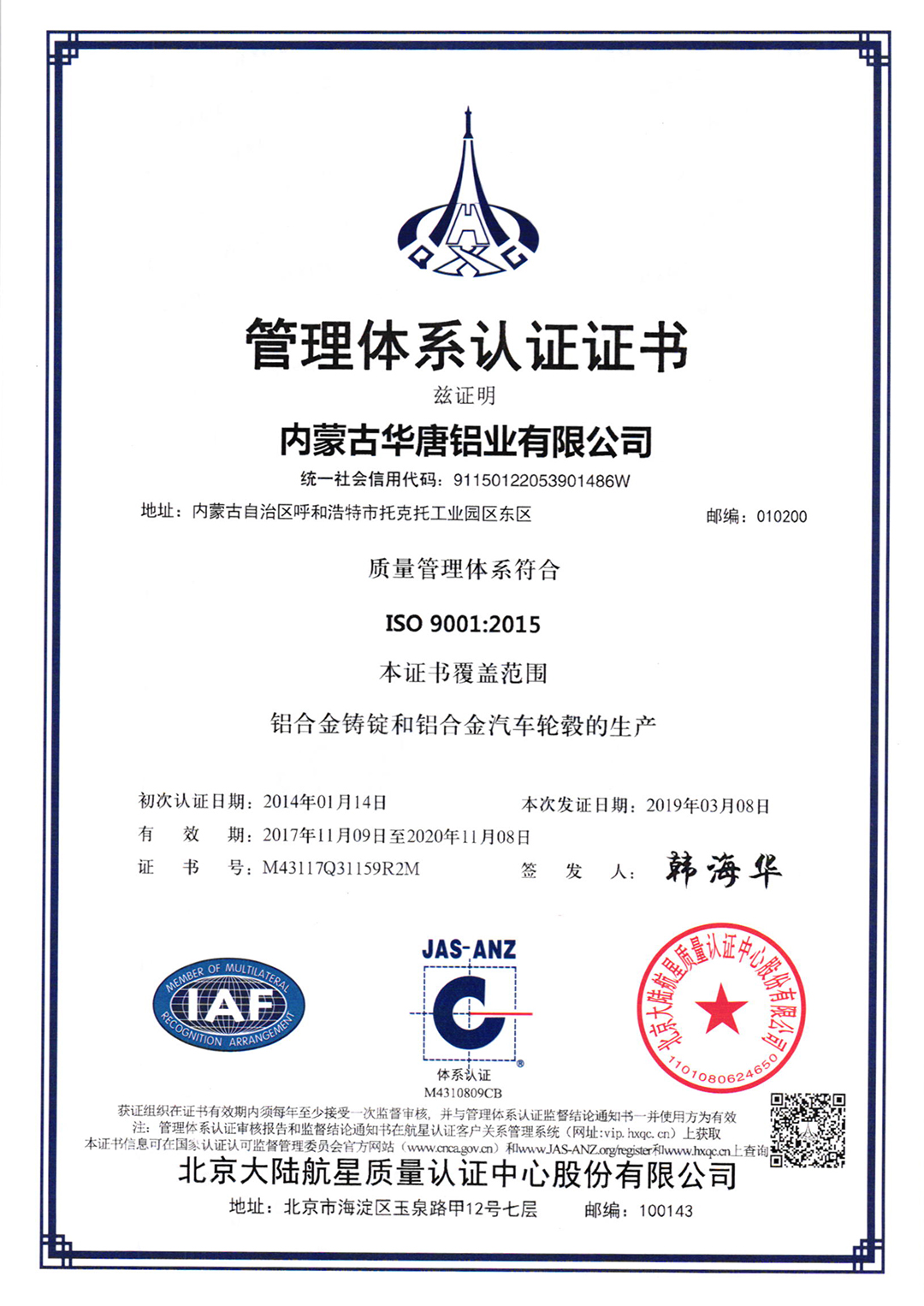

公司通过了 IATF16949-2016 汽车配件质量管理体系、武器装备质量管理体系及 9000 管理体系认证;已取得多项发明和实用新型专利,发表多篇专业技术论文,通过了高新技术企业认证。公司坚持自主知识产权,建立了完善的研发与“智能制造”体系,并立足于科技与工艺的完美结合。

公司的核心竞争力为:原料充足、“短流程、用余热、不重熔、一个流、不落地、整体可控”、智能制造(离散型制造流程化)、互联网平台。公司注重人才培养,各类技术人员通过运用 ERP、PLM、PDM、MES 以及西门子 NXUG 和主体库 WMS 等系统,大幅度改善了管理效率,缩短研发时间,提高了能源利用率、产品合格率。再通过物联网与大数据集成技术,实时处理内、外部多元的海量数据,构建以数据生命周期管理为核心的数据管理平台,通过可视化监控与管理数据流程,快速将原始数据转变为业务洞察数据的处理能力,准确地掌握客户信息,实现产品从传统型大批量制造升级为大批量订制型制造,实现了离散型制造流程化,保证了产品性能,产品结构达到了最优化设计。

公司拥有多年的铝制品生产经验,聚集着多名行业专家,专业生产 6000 系铝合金产品。并可根据不同的用户需求,通过适量比例微量元素的添加调整不同的合金成份,生产出满足用户需求的高强韧及轻量化产品。

公司凭借自身专业化的科学管理,利用云平台、大数据、物联网、移动互联、人工智能,实现自感知、自学习、自决策、自执行、自适应。公司本着“服务社会,坚持走绿色发展道路”的企业使命;以“专注汽车轻量化,助力中国汽车智能制造”为企业愿景;以“智能制造,创建世界品牌”为企业目标;以“安全、创新、节能、环保、舒适”为宗旨。坚持以客户为导向,满足并超越客户期待的服务理念;实现产品“高强韧、轻量化、品质优、同质量、低耗能”的生产理念,致力于高品质锻旋铝合金车轮大批量订制智能制造流程化生产,打造成为中国汽车智能制造之轻量化锻旋铝合金车轮产业基地。

我们的优势

产品生产智能制造,节能环保;产品唯一二维码,全程可追溯;

产品性能高强韧、重量轻;产品质量优且一致;

集成化智能产品。

内蒙古华唐铝业有限公司

Inner Mongolia Huatang Aluminum Co., Ltd. is a lightweight aluminum alloy production enterprise engaged in scientific research, production and sales. The company focuses on automobile lightweight and helps China's automobile intelligent manufacturing. With an annual output of 220000 tons of aluminum bars and 3 million high-precision lightweight aluminum alloy wheels, 800000 of which are manufactured intelligently by forging and rotating aluminum alloy wheels, the project has won the approval of the Ministry of industry and information technology of the people's Republic of China for "Application of new intelligent manufacturing mode of forging and rotating aluminum alloy wheel hub", and a new intelligent manufacturing mode factory of domestic forging and rotating aluminum alloy wheel has been built.

The company was established in Tuoketuo Industrial Park, Hohhot City, Inner Mongolia on August 23, 2012, with a registered capital of 90 million yuan, a total investment of 500 million Yuan, an area of 95649 square meters, and a total construction area of about 50000 square meters.

The company has passed the certification of IATF16949-2016 automobile parts quality management system, weapon equipment quality management system and 9000 management system; it has obtained a number of invention and utility model patents, published a number of professional technical papers, and passed the certification of high-tech enterprises. The company adheres to independent intellectual property rights, establishes a perfect R & D and "intelligent manufacturing" system, and is based on the perfect combination of technology and technology. (the company has authorized 1 invention patent, applied for 7 invention patents, authorized 19 utility model patents, obtained 6 software copyrights, published 3 technical professional papers, and formulated 3 enterprise standards.)

The core competitiveness of the company is: sufficient raw materials, "short process, waste heat, non remelting, one flow, non landing, overall controllable", intelligent manufacturing (discrete manufacturing process), Internet platform, production university research cooperation. The company pays attention to the strategic training of talents, and cooperates with Tsinghua University, Beijing Institute of mechanical and electrical research, CNR, Beijing lightweight Research Institute, Beijing Automotive Technology Institute, etc. By using ERP, PLM, PDM, MES, Siemens nxug, WMS and other systems, all kinds of technicians trained by the company have greatly improved management efficiency, shortened R & D time, and improved energy utilization rate and product qualification rate. Then through the Internet of things and big data integration technology, real-time processing of internal and external multiple massive data, building a data management platform with data life cycle management as the core, through visual monitoring and management of data process, quickly transform the original data into the processing ability of business insight data, accurately grasp customer information, and realize the upgrading of products from traditional mass manufacturing to Mass customization manufacturing realizes discrete manufacturing process, ensures product performance and optimizes product structure.

The company has many years of aluminum production experience, gathered a number of industry experts, specializing in the production of 6000 series aluminum alloy products. According to different users' needs, different alloy components can be adjusted by adding appropriate proportion of trace elements to produce high strength, toughness and lightweight products that meet users' needs.

With its professional scientific management, the company uses cloud platform, big data, Internet of things, mobile Internet and artificial intelligence to realize self perception, self-learning, self-decision-making, self-implementation and self adaptation. The company adheres to the corporate mission of "serving the society, adhering to the green development road"; takes "focusing on automobile lightweight, helping China's automobile intelligent manufacturing" as the corporate vision; takes "intelligent manufacturing, creating a world brand" as the corporate goal; and takes "safety, innovation, energy conservation, environmental protection, comfort" as the tenet. Adhere to the customer-oriented service concept to meet and exceed customer expectations; realize the production concept of "high strength, light weight, high quality, the same quality, low energy consumption" of products, commit to high-quality forged aluminum alloy wheel mass customization intelligent manufacturing process production, and build into China's automobile intelligent manufacturing lightweight forged aluminum alloy wheel industrial base.

Our strengths

Intelligent manufacturing, energy saving and environmental protection; unique two-dimensional code, traceable in the whole process;

The product has the advantages of high strength and toughness, light weight, excellent and consistent quality;

Integrated intelligent products.

Inner Mongolia Huatang Aluminum Co., Ltd

企业使命

Enterprise Mission

为客户创造价值,为企业创造效益

为员工创造福利,为社会创造财富

企业价值观

Corporate Values

安全理念

Safety concept

人才理念

Talent concept

服务目标

Service target

服务理念

Service idea

生产理念

The concept of production

企业宗旨

Enterprise Purpose

企业愿景

Enterprise Vision

企业目标

Enterprise Target